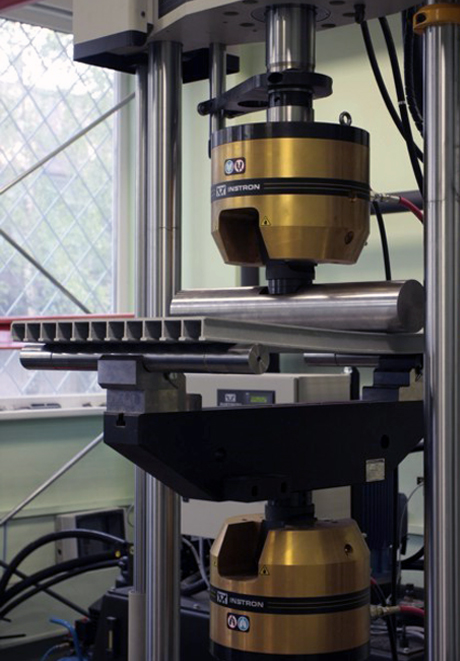

Dynamic equipment

INSTRON 8802

Instron® 8802 is a versatile servo-hydraulic fatigue test device for static and dynamic loading. The 8802 machine provides several advanced materials testing solutions.

Servo-hydraulic fatigue test device for static and dynamic loading, with the ability to set constant, creeping or variable loads (cyclical) in tension, compression or gravity. To determine the properties of static and dynamic materials for materials such as: plastics, fabrics, wood, composite materials. The load range is up to 250 kN. The machine is equipped with Dynacell type transducers, which includes machine components for inertia compensation mechanisms. The components of the machines are fatigue-resistant, thus, are particularly suitable for testing fatigue of materials. Precision class according to ASTM E74 class A / A1 standard.

Specification

Main function:

The static and dynamic determination of bulk materials, such as plastics, fabrics, wood, composite material, with a constant, increasing or variable load (bicycles) during tension, compression or bending.

Parameters:

- Maximum load / compression: 250 kN

- Maximum weight: 1330 kg

- Loading wheel height: 1975 mm

- Total height: 3961 mm

- Loading wheel width: 1060 mm

- Frame overall width: 1120 mm;Lloading area: 664 mm

- Working temperature: +20 … + 90 ° C

- Relative humidity: 20 … 95%

Services:

Static and dynamic determination of various materials, such as plastic, fabric, wood, composite materials with constant, increasing or variable load (cycling) during tension, compression or bending.

INSTRON 8872

Servohydraulic fatigue testing system which is designed for static and dynamic loading with the opportunity to put a constant, growing or changing load (cycling) in tension, compression or bending. Static and dynamic material properties can be determined for materials such as: metals, plastics, fabrics, wood, composite materials. Load range is 250 kN. The machine is equipped with Dynacell type load cell which includes machine components, inertia compensation mechanisms. Machine components are fatigue resistant, thus, it is particularly suitable material fatigue testing. Accuracy class according to ASTM E74 Class A/A1 standard.

Specification

Parameters:

- Maximum load / compression: 250 kN

- Maximum weight: 1330 kg

- Loading wheel height: 1975 mm

- Total height: 3961 mm

- Loading wheel width: 1060 mm

- Frame overall width: 1120 mm

- Loading area: 664 mm

- Working temperature: +20 … + 90 ° C

- Relative humidity: 20 … 95%

Services:

Static and dynamic determination of various materials, such as plastic, fabric, wood, composite materials with constant, increasing or variable load (cycling) during tension, compression or bending.

ElectroPuls E3000

The ElectroPuls™ E3000 is a state-of-the-art electrodynamic test instrument designed for dynamic and static testing on a wide range of materials and components.

The ElectroPuls is a state-of-the-art electrodynamic test instrument designed for dynamic and static testing on a wide range of materials and components. Compression, tension and bending loads could be applied. High dynamic performance, capable of performing to more than 100 Hz.

Specification

Main function:

Patented, oil-free linear motor technology for clean conditions. Designed for both dynamic and static testing with various materials and components. High dynamic performance that can reach over 100 Hz, dynamic load of ± 3000 N and long lasting static load ± 2100 N capacity Electrically powered from single-phase main power supply, no hydraulic or pneumatic air supply Required temperature-controlled air cooling system High rigidity, precision alignment Two-column load frame with actuator in upper bracket Universal T-shaped broom table adjustable and non-regular handles and copies. Compact tool – The frame has a storage area of less than 0.3 m² (3.2 ft²).

Parameters:

- Dynamic Force power: ± 3000 N (± 675 lbf)

- Linear stroke: 60 mm (2.36 in)

- Daylight opening (max): 855 mm (33.6 in)

- Maximum with actuator during the average stroke Power supply: single-phase mains Configuration: twin -load with an actuator in the upper bracket.

- Lifts and locks: electric operated hand lifts.

Services:

Cyclic tests.

Tensile, compression, tensile strength.

Impact strength, joint strength, inserts.

Mechanical testing of textiles, composite materials, metals, ceramics.

Instron ElektroPlus E10000

The ElectroPuls E10000 Linear–Torsion machine is a state-of-the-art, all-electric test system designed for dynamic and static testing on a wide range of materials and components.

The ElectroPuls E10000 Linear-Torsion machine is the most advanced, all-electric test apparatus for dynamic and static testing with a wide range of materials and components. Compression, tension and bending loads can be applied.

Specification

Parameters:

- Linear dynamic volume: ± 10,000 N (± 2250 lbf)

- Torching power: ± 100 Nm (± 800 lb) Linear stroke: 60 mm (2.36 inches)

- Rotation: ± 135 ° as standard (reconfigure with ± 16 revolutions with Instron Service)

- Fluorescent hole (max): 877 mm (34.5 inches) maximum with actuator on average stroke

- Power supply: single-phase current

- Configuration: two-level floor instrument with actuator in the upper bracket

- Lifts and locks: electric powered lifts with manual levers

- Mounting: floor, vertical

- Mechanical testing of textiles, composite materials, metals, ceramics

Service:

Cyclic tests.

Tensile, compression, tensile strength, torsion test.

Fragmentation, joint strength, inserts.

Mechanical study of textiles, composite materials, metals, ceramics.